Tactile paving consists of six different types of standardised paving designs with distinct, raised surface patterns. Visually impaired pedestrians can detect the tactile paving slabs underfoot or by using a cane and interpret the meaning of these patterns.

According to the NHS, there are over 2 million people in the UK dealing with sight loss. Of these, 340,000 people are registered as blind or partially sighted. For those living with vision loss, a simple walk down the street can become full of hazards and anxiety.

Tactiles are a special type of paving which provide essential cues to help people navigate footpaths safely and confidently. Tactile paving slabs alert pedestrians to hazards and provide information. For example, it can alert visually impaired pedestrians to crossing points, platform edges and shared cycleways.

By planning and installing tactile paving slabs thoughtfully and consistently, city planners can help visually impaired pedestrians experience greater independence and mobility.

Tactile paving was invented by Seiichi Miyake in 1965 in Japan. In 1985 it was officially implemented in Japan and in the 1990s its use expanded to the rest of the world.

Government guidance states that tactile paving should be simple, logical, and consistent. Simple and logical layouts will minimise confusion for people encountering an area for the first time. The guidance supports the creation and maintenance of an inclusive and accessibly built environment in compliance with the Equality Duty, set out in the Equality Act 2010.

Consistency is vital

The importance of consistency cannot be overstated. Those responsible for fitting tactile paving slabs must ensure that the messages conveyed by it are clearly understood.

Inconsistencies in application can cause the paving to be misinterpreted underfoot. This could result in pedestrians finding themselves in potentially hazardous situations. For example, they could walk into a road without knowing that they are in a road or stray too close to a platform edge without realising.

A government survey completed in 2005 found that more than half of tactile paving installations in the cities surveyed had something wrong with them. Of these, 12% of the tactile paving slabs were the incorrect colour and 4.2% were the wrong pattern.

Using the correct type of paving ensures the safety of all pedestrians

It is important to refer to the government guidelines on tactile paving installation for your specific situation to ensure accuracy and consistency. However, there are several general guidelines that are applicable in all situations.

There are six types of tactile paving that are currently used in the UK. Each type of paving is intended to be obvious enough to be recognised by visually impaired pedestrians. However, the detailing on the tactile should not be so extreme that the paving becomes a hazard itself.

| Official Name | Other Names | Design | Uses |

| Blister Surface | Pedestrian Crossing Tactile Paving | Flat topped ‘blisters’ arranged in a square pattern | Indicates location and type of pedestrian crossings |

| Corduroy Hazard Warning Surface | Hazard | Rounded raised bars | Indicates the presence of specific hazards such as steps |

| Platform Edge (On-Street) Warning Surface | Lozenge Tactile Paving | Large ‘lozenge’ shaped bumps | Indicates the edge of an on-street light rail transit (LRT) platform |

| Platform Edge (Off-Street) Warning Surface | Offset Blister | Flat topped ‘blisters’ arranged in an offset pattern | Indicates the edge of an off-street railway platform – only for use at the edge of railway and underground station platforms |

| Segregated Shared Cycle Track / Footway Surface | Ladder / Tramline, Cycleway Tactile Paving | Flat topped bars extending across the entire block | Indicates which side of a shared footpath / cycle track is for pedestrians and which for cyclists |

| Guidance Path Surface | Directional | Flat topped bars with rounded edges | Helps to guide pedestrians through open paved areas and around obstacles |

Note: There was originally a seventh type of tactile paving called Information Surface. This soft, rubbery surface was intended to alert pedestrians to services such as ATMs, post boxes, and the entrance to civic services.

However, it wasn’t widely used and is no longer included in government guidance on tactile paving.

A standard tactile paving slab is 400 x 400mm. Government-recommended arrangements are given in increments of 400mm, so using this size will offer consistency and conformity.

However, there is no regulation to say that the tactile slabs must be this size, indeed both larger and smaller sizes are commonly available. This can be useful for paving areas that require a greater flexibility and where larger units would otherwise have to be cut to size.

Because of the nature of tactile paving, it is essential that it doesn’t wear down quickly. This should always be considered when choosing a material.

Tactile paving slabs are manufactured in a range of materials. Concrete and granite are commonly used, but in some areas, metal studs are utilised by fixing them to the existing paving surface, often using adhesives, to create a blister surface.

Another highly durable and significantly more cost-effective option are the ranges of adhesive or stick on tactile paving slabs. These are available primarily in a resin composite material, but there are also options in glass reinforced plastic (GRP) with anti-slip surfacing.

They offer great advantages over the use of concrete slabs. The tactile slabs are laid on top of the existing pavement, so it is far quicker and easier to install them. No excavation or heavy plant machinery is required, and the tiles are light and easy to handle.

Large installations of tiles can be achieved in much shorter timeframes, returning the areas to public use with minimised disruption. Moisture tolerant adhesives are also available for exterior installations, even in damp conditions.

Adhesive tactile paving can also be layered over access hatches and inspection covers, ensuring that the area of tactile paving is consistent.

Some sites may call for the use of combinations of these techniques and materials.

In the government survey cited above, it was found that the colour of tactile paving was often chosen to match with the rest of the pavement, which contradicts its purpose.

Tactile paving should contrast with the pavement around it. This is to make the tactile paving as obvious as possible for people who are partially sighted. A government study published in 2020 reported that 44% of the visually impaired people surveyed used something other than surface texture (most notably colour) to understand tactile paving. This rule may be relaxed when used in conservation areas.

Blister tactile paving used at a controlled crossing should always be red. Red should never be used for any other purpose. Other than this, there are no specific colour requirements.

When choosing a colour for tactile paving, planners should also consider how the colour and material will look under different lighting and at different moisture levels. Effective tactile paving should contrast with the pavement around it even in poor lighting and wet conditions.

Some situations call for the use of a specific colour by regulation of the property duty holder. For example, Network Rail stipulated the use of Platform Edge (Off-Street) tactile in high-visibility yellow on a railway platform where non-stopping trains can pass through the station at speed.

Our tactile paving slabs are available in a range of colours, so the most appropriate or impactful contrast can be achieved for the location.

Each type of tactile paving is used to convey different information.

Blister paving has flat topped 5mm ‘blisters’ arranged in a square pattern. The blister surface is used to indicate where there is a pedestrian crossing with a dropped kerb.

The tactile paving will cross the entire area between one dropper kerb and the other. How far back the tactile paving should go from the edge of the road depends on the type of crossing.

Normally, the pavement should be laid at a depth of 800mm, though there are instances where a 400mm of 1200mm depth is necessary.

A controlled crossing is where the traffic must stop for pedestrians to cross. This could be either a give-way crossing where traffic must yield to pedestrians or a signal-controlled crossing where the traffic will be stopped by a signal to allow pedestrians to cross.

Examples of controlled crossings:

Give-way

Signal-controlled

The blister paving used at a controlled crossing should always be red. Red tactile paving should only ever be used at a controlled crossing. If the surrounding pavement is also red, a border should be included around the tactile paving to make it stand out more. This border should be at least 150mm wide.

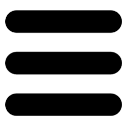

At controlled crossings, where the crossing is in the direct line of travel for pedestrians, the tactile paving should be laid to a depth of 1200mm from the dropped kerb. At all other controlled crossings, it should be 800mm deep.

The tactile paving should be laid to align with the direction of crossing, since many visually impaired people use the alignment of the paving to orient themselves. Because of this, the paving might be at an angle to the kerb.

In instances where there is a pedestrian operated signal control, a ‘leg’ or ‘stem’ should be extended into the footway to indicate which side the control is on.

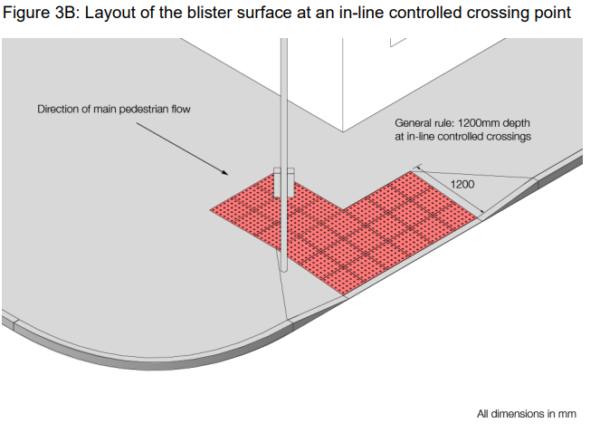

An uncontrolled crossing is where the pedestrian does not have right of way and must wait for a safe break in the traffic to cross the road. The blister paving at these crossings can be any colour except red, provided that it contrasts with the surrounding pavement.

At an uncontrolled crossing, the blister paving should cover the whole area where the dropped kerb is level with the road. As with controlled crossings, the paving should align with the direction of crossing and not the edge of the kerb.

The required depth of paving depends on the specifics of the crossings, but in general a depth of 400mm is required at an inset side road crossing, 800mm for a crossing away from a junction where the kerb is level with road, and 1200mm where the crossing is in line with the direction of travel.

Hazard or corduroy tactile paving conveys the message ‘hazard, proceed with caution’. It has rounded bars 6mm high, 20mm wide with a 50mm centre to centre spacing, running transversely across the walking direction. They can be of any colour, other than red, that achieves a good visual contrast with the walkway surface.

Government guidance should be consulted for specific or complex situations.

Overall, the paving should be laid 400mm back from the edge of the first step of a flight of stairs. The paving should be 800mm deep and extend 400mm on either side of the steps (though care should be taken no to block access to ramps or lifts).

Similarly, paving should be laid 800mm deep to indicate the start of an LRT ramp and 400mm or 800mm deep at a level crossing.

The Lozenge, or on-street warning surface, is identified by large raised rounded ‘lozenge’ shapes. Six ‘lozenges’ fit on to one 400 x 400mm tactile tile or paver. The raised portion of the paving should be 6mm high.

In similarity to other tactile paving, lozenge paving can be any colour except red and should contrast with the surrounding pavement.

Lozenge tactile paving alerts pedestrians that they are approaching the edge of an on-street LRT platform. It was introduced because it was thought that the off-set blister design used in rail stations would be too similar to the blister paving used in pedestrian crossings.

A new design was therefore created specifically for on-street railway platforms.

Lozenge paving should be laid at least 500mm from the platform edge at a depth of 400mm. The flat edge of the raised ‘lozenges’ should be parallel to the platform edge and run for the entire length, including the access ramps.

As stated above, the base of the LRT access ramp should be indicated by the corduroy hazard paving.

The Platform Edge (Off Street) warning surface, also know as Offset Blister tactile paving is similar to the blister pedestrian crossing pattern, except for the 5mm flat-topped ‘blister’ rows are arranged to be offset or staggered from adjacent rows.

This tactile paving warns pedestrians they are approaching the edge an off-street rail platform. These include heavy (mainline) rail, underground, tram or other LRT platforms.

Off-set blister paving can be any colour other than red and should contrast with the platform around it.

Off-set blister paving should be laid a minimum of 500mm from the platform edge (immediately after any coping stone). The blister paving should be laid 400mm deep along the entire platform edge. The paving slabs should be laid so that the lines of blisters are parallel to the platform edge.

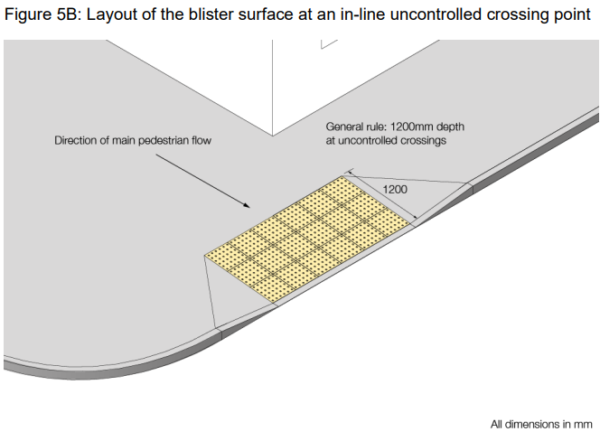

Segregated shared cycle track / footway surface or ‘Shared route’ tactile paving modules have raised flat bars, 5mm high, 30mm wide and with 70mm spacing. The bars go all the way to the edge of the tactile surface module.

As the name suggests, this type of paving is used on shared cycle and footpath routes to indicate the entry point of each user type. It is normally buff in colour but can be any colour, other than red, which gives good contrast against the surrounding surface.

The orientation of the bars indicates whether the entry is for the cycleway or the footpath. On the footpath, the bars should be perpendicular (ladder surface) to the direction of travel, whilst on the cycleway they should be parallel (tramline) to the direction of travel.

Shared routes will also have a 150mm wide raised central delineator strip with sloping sides to help pedestrians stay on the correct side of the surface.

Shared route tactile paving should be used at the start and finish on the route and at junctions. It should also be used at regular intervals throughout.

The paving surface should extend across the full width of the footway and cycle track to a depth of 2400mm at the start and finish and at any junctions. While any repeating sections only require a depth of 800mm.

Guidance path surface or Directional tactile paving has 5.5mm high bars, 35mm wide and spaced 45mm apart, with rounded ends which do not reach the edge of the paving unit. Like other tactile paving, it should contrast with the surrounding pavement and can be any colour except red.

This paving is used to guide pedestrians through open paved spaces where other directional cues, such as kerbs, railings or a property line are not present. The paving may also be used to guide pedestrians around obstacles such as street furniture.

The raised bars should run parallel to the direction of travel. Before right angle turns or junctions, a 1200mm long section of perpendicular bars should be included to warn pedestrians of the change. The paving should be 800mm wide throughout.

To remain functional and effective, tactile paving must be properly maintained and replaced when needed. For example, if the raised portions of blister tiles are allowed to wear down below 3mm in height, they will be indistinguishable by pedestrians. This will mean that the tactile paving will cease to function as intended.

For other types, while their features will still be effective at the lower allowable tolerance of 4.5mm, if the raised portion of these tactile slabs are allowed to erode below that, their effectiveness will reduce. It is therefore especially important to select a tactile paving which is made from a hard-wearing material and one which is easy to replace in the future.

Most of our tactile paving slabs are adhesive surface mounted. They are made from either extra durable resin composite (built and tested to offer up to seven times the wear characteristics of concrete modules), or from GRP with an ultra-tough anti-slip surface coating. Take a look at our What Is GRP guide to learn more about its benefits.

27th March 2020

We would like to reassure all customers and enquirers that we remain open for business, while carefully following Government guidelines issued here:

https://www.gov.uk/coronavirus

The majority of our administration staff are working remotely and we have rostered production staff to make numbers available to meet demand.

We are able to provide the full range of our standard products from stock to serve any ongoing requirements you may have and will be pleased to receive any invitations to quote for future projects.

At the present time, in accordance with social distancing regulations we will not be conducting face to face meetings with business partners until further notice. However it may be possible to arrange video link meetings if required, please contact us for further information.

Collections of orders from our workshops are possible, by prior arrangement only please and visitors are reminded to observe the standard 2m distancing rules, for the safety of all.

Our transport partners are all providing us with a normal service.

We will update this statement if required and following any further guidance issued by the UK Government.

We wish you well.